Application Area

BarkerBille manufactures fans for a wide range of industries. The company specializes in designing and supplying durable and durable fans for customers in the food, energy and marine sectors. Our engineers are highly trained and have many years of experience, and can be tailored to our customers to meet the diverse needs of our customers.

Different industry applications, the requirements for fans are also very different. Therefore, as a wind turbine supplier, it is necessary to have a wealth of experience in designing a fan for a specific industry in order to understand the customer's needs. And that's why you prefer BarkerBille. With more than 50 years of experience in designing and manufacturing wind turbines, we understand your needs.

Energy efficiency and stable performance are the basic commonalities of all BarkerBille fans, giving you a unique experience. In addition, we can customize the turbine solution for specific projects, which are CE certified and ATEX certified (ATEX specification for high explosive hazardous environments).

Food and Pharmaceuticals

BarkerBille uses years of experience to design and manufacture wind turbines for the food, pharmaceutical and pharmaceutical, and dairy industries. Our stainless steel fans and acid-resistant material fans are well suited to meet the stringent hygiene requirements of the turbine during operation and are easy to clean.

The fans used in the food and pharmaceutical industries are manufactured according to BarkerBille's hygienic standards to ensure the safest and most hygienic design.

All fans can be configured with CIP for internal cleaning. BarkerBille provides customers with CIP nozzle design and layout, installation advice and professional advice to ensure that the fans receive CIP cleaning.

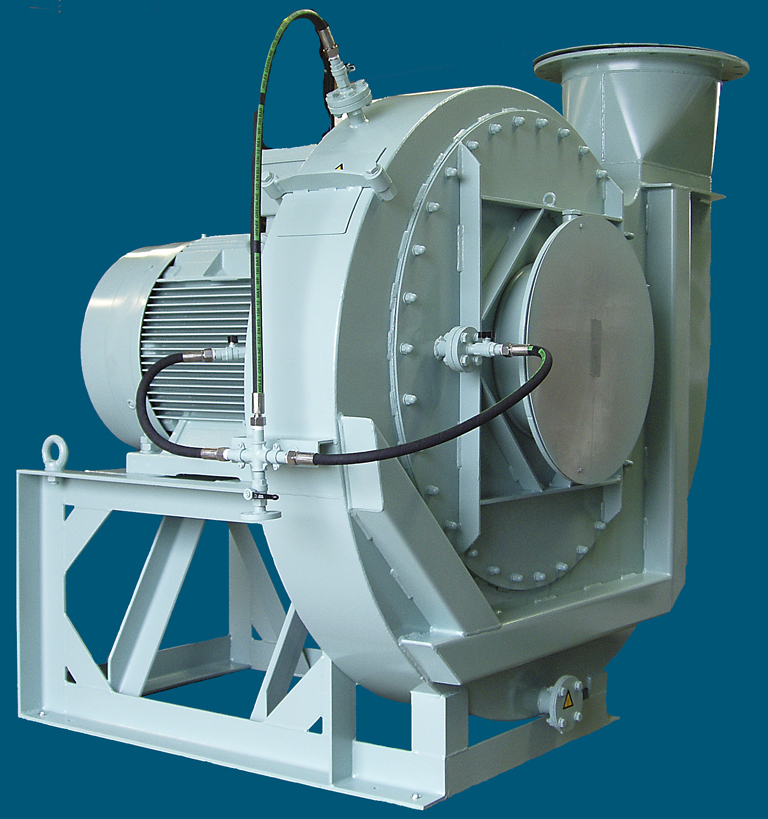

Marine and Offshore Platforms

BarkerBille has designed and manufactured a wide range of different types of wind turbines for marine and offshore platforms. The common features of these wind turbines are energy efficient, high quality and able to meet customers' stable operation of wind turbines. Claim.

Thanks to years of valuable experience in the marine marine sector, BarkerBille's wind turbines meet the specific requirements of the industry and can be tailored to the customer's needs. Individual adjustment.

●Inert gas blower

●Fume desulfurization fan (FGD)

●Fume recirculation fan

●Inert gas fan

●FPSO (Floating Production Storage and Offloading Device) Combustion Fan

●Ventilation fan

●Combustion Oxidation Fans

Boiler

The hot water produced by the onboard boiler can meet the demand for hot water in daily life and heating systems. The centrifugal fan of BarkerBille provides safe and stable air for the boiler combustion process. According to the customer's requirements, we design the fan and adjust the fan design according to the actual installation environment.

Inert Gas

To minimize the risk of fire and explosion of the tanker, an inert gas is trapped between the stored oil and oxygen (air). The inert gas is generated by an inert gas system on the tanker and is delivered to the storage tank via a fan boost. BarkerBille produces fans for inert gas systems, and the fan overcurrent components are surface treated with a special coating.

Incineration

Incineration can be used to recover energy from waste and achieve waste reduction. In order to safely and environmentally treat waste, an incinerator is required. In all incineration processes, it is important to ensure accurate and stable replenishment, in order to ensure that particulate matter has been fully incinerated before being released into the air.

In some areas of expertise, there are many benefits to incineration of certain types of waste, such as pathogens and toxins in medical waste and some hazardous waste, which can be destroyed by high temperature incineration. .

For major manufacturers of marine incinerators and land incinerators, BarkerBille has been a long-term stable supplier of high quality medium and high pressure fans. In some cases, BarkerBille also provides fans directly to the user's project.

Ocean Platform

BarkerBille has expanded its product portfolio to include wind turbines and silencers for use in offshore platforms.

The harsh environment in the ocean puts high demands on the wind turbine. BarkerBille guarantees the reliability of wind turbine surface treatment and welding, and selects the right material to make the fan according to the environment. We can provide various classification societies certification. Before the fan is shipped, the customer can perform a thorough inspection of the completed fan, including performance testing.

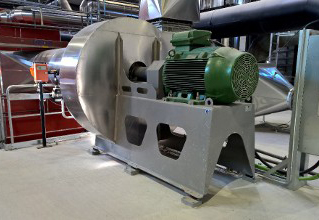

Energy and Power

For many years, BarkerBilleA/S has been experienced in supplying process fans for the energy and power industries, incineration plants, etc.

Our fans are used in various power plants, heating plants, incineration power plants, cogeneration and renewable energy power generation projects. These plants use biomass fuels such as wood, wood chips, hay, domestic waste, agricultural waste, biogas and other waste or use fossil fuels including oil, natural gas and coal as fuel.

The traditional incineration plant is a comprehensive facility for heating a large number of family units. The complex building complex and processing technology need to be equipped with many different types of fans.

We provide high efficiency fans to meet the requirements of energy saving and environmental protection.

BarkerBille's fans provide the combustion gas required for the incineration process, and its performance depends on the real-time demand for gas from the boiler during incineration. The gas flow can be adjusted and controlled by the air volume control valve and the frequency converter at the air inlet of the fan.

In order to recover and utilize the energy in the exhaust gas, the exhaust gas is injected into the heat exchanger for heat exchange before being discharged into the atmosphere. In this way, the exhaust gas with too low temperature cannot be naturally discharged into the chimney, so a flue gas fan is required to assist the exhaust.

Another function of the flue gas fan is to create a partial vacuum in the boiler to minimize the risk of exhaust gas leakage into the atmosphere.

Fan type

●Primary fan & ndash; transporting air from the grate to the grate

●Secondary Fan – Transporting air from the waste tank to the secondary air nozzle

●Cooling fan – delivers wind to the cooling inlet of the feeder and grate

●Induced draft fan and blower– arranged after the flue gas purification device, the flue gas is discharged to the chimney via the condenser, and the function of the flue gas condenser is to prevent the saturation of the flue gas temperature from being too high. appear.

● Sealing Fans

●Recycling Fans

Food and Pet Food

At first, BarkerBille's fan selection design process was developed to meet the demand for high quality wind turbines in the food industry. Our wind turbines have long been used in the processing of various grains and seeds, and are still one of the most important applications for our wind turbines.

In the pet food industry, we design wind turbines to meet strict hygiene regulations and food processing standards. Fan design that meets hygienic standards is critical to ensuring food safety.

Chemical Industry

For many years we have designed a large number of fans for the chemical industry. BarkerBille's chemical fans,

Designed for highly corrosive environments with long life.

BarkerBille offers stainless steel fans and acid-resistant material fans. If the customer has special requirements for the fan seal, we can offer different shaft seal options.

All fans are pressure tested at the factory prior to shipment.

Other Process Fans

BarkerBille also provides fans for a variety of different processing techniques used to process the following materials:

●Wood

●Cardboard and paper

●Concrete

●Wood sticks

●Steel and metal

●Plastic

● Nonwovens

● When designing wind turbines for the above industries, the types and loads of materials transported by the system are our special focus to ensure that the turbine design meets the requirements of the application.