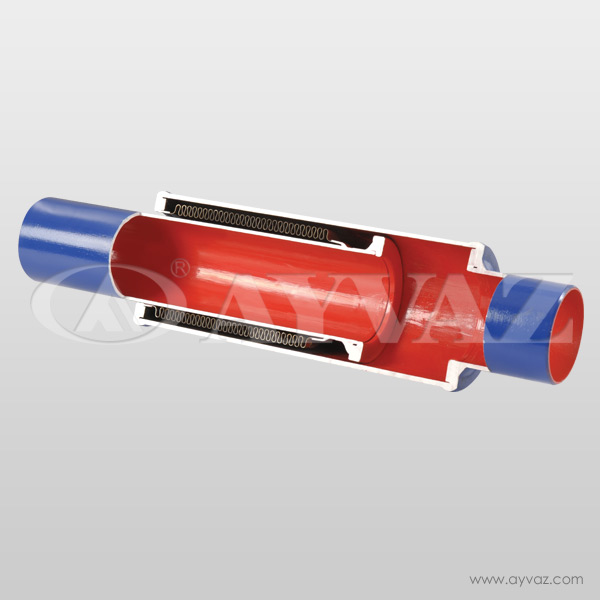

Only by increasing the number of corrugations in the bellows, a larger amount of thermal expansion can be compensated by the axial expansion joint, but this increases the possibility of torsion. The inner sleeve can be used to reduce the torsion, but at the same time they also reduce the displacement capacity of the expansion joint. Ayvaz's external compression expansion joints provide the most suitable solution for this situation.

Compensation displacement

X-axis - compressed axial expansion joint changes the flow direction and transmits pressure to the external bellows, so that the resistance of the externally pressurized bellows to high pressure and torsion increases. This sturdy construction safely compensates for large movements.

X-axis - Advantages of compressed axial expansion joints

Easy to compensate for large telescopic displacement

Reducing the number of axial expansion joints, saving time and cost

Use the smallest area

Eliminate axial errors and increase system security

Use an internal guide ring in its design to provide a highly stable structure for the connection

Structure

Bellows material: Stainless steel AISI 321 (optional 304, 316L, 316TI, 309)

Pipe material: Standard carbon steel St.37.2, materials can be customized according to customer requirements

Connection type: fixed and floating flange, end welding

Flange material: Standard carbon steel St.37.2, materials can be customized according to customer requirements

Inner sleeve: AISI 321 (optional 304, 316L, 316TI, 309) available upon request

Working conditions

Working temperature: -80C°/+600C°

Working pressure: Different pressure levels can be customized PN 2,5/6/16/25/40/64

Nominal diameter: DN 25 (1”)- DN 1500 (60”)

Product Manual

Click here to download External Pressure Expansion Joints Manual

Download Manual (PDF)