UCP series

Features and uses:

Product Overview

UCP series vortex pumps are ultra-pure varieties developed for the food, pharmaceutical, and semiconductor cleaning industries. The pump body is completely precision machined and precision ground and polished by stainless steel calcined materials. According to the application requirements, the liquid surface can be supplemented with special surface treatment processes such as non-dynamic treatment and PTFE coating treatment to prevent metal ions from overflowing and satisfying ultra-pure. Liquid supply requirements.

Product Features

● Simple structure without hygienic corners

The structure is simple, the design completely eliminates the dead corners, and avoids the space for microbial breeding;

(There is no possibility that the corrugated pump or diaphragm pump has too much contact area and the risk of breeding and residual microorganisms is high)

● Thorough surface treatment

Precision processing of wetted parts, supplemented by special grinding and surface treatment, can achieve ultra-pure use requirements;

●Long-term stability performance

Because there are no bellows, diaphragms or valves that reciprocate the bellows pump or diaphragm pump, it not only ensures long-term stability and service life, but also saves maintenance costs ;

●Excellent heat resistance and durability

The parts of the pump are made of 316L stainless steel, the mechanical seal is made of silicon carbide and resistant to heat-resistant PTFE, and the resin pump can't correspond to 100°C or above. High temperature conditions can also be used normally;

● Prevent microparticles (fine impurities) from happening

Using an external mechanical seal, supplemented by a shaft seal to flush the venting device, impurities less than 0.5 microns can be controlled within one.

Product Usage

General Industrial Cleaning Equipment

Pure water ultrapure water delivery equipment

Food, liquid delivery equipment and medical equipment

Microelectronics components, printed circuit board cleaning equipment

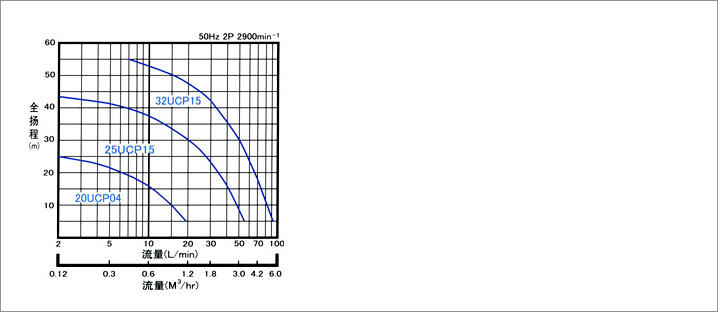

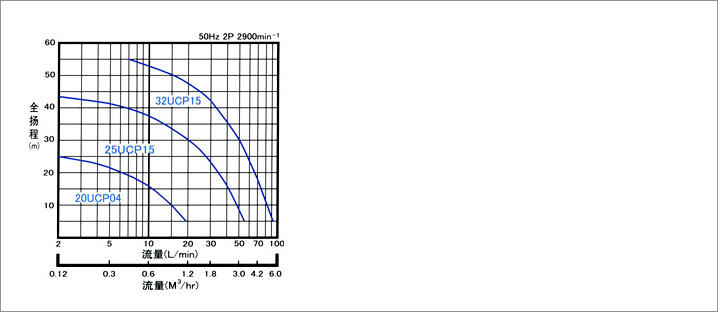

Performance curve: