CTS series sanitary pump

Features and uses:

Product Overview

CTS series centrifugal pumps are new sanitary products developed to meet the liquid delivery needs of food and beverage machinery and pharmaceutical equipment.

This series of products are designed according to the domestic and international standards of food and pharmaceutical related industries, and in the entire production process, the materials are strictly in accordance with the above standards for material purchase acceptance, processing and surface. Handling, assembly and performance testing. The actual performance and operational stability of the product are equivalent to or better than similar products at home and abroad.

This series of products can not only correspond to low and medium viscosity liquids, but also to contain suspended solids or corrosive liquids, suitable for transporting liquids and dairy products with hygienic requirements. , beverages, beer, food additives, cosmetics, biological agents, fine chemical liquids, etc.

Product Features

●The pump body and impeller are innovatively designed to optimize the flow characteristics of the pump and improve the overall performance of the pump;

● Designed in strict accordance with hygienic product specifications, completely eliminates sanitary corners, and can perform CIP cleaning and SIP sterilization on site;

●The flow surface is finely polished and degreased to meet food and pharmaceutical grade acceptance criteria;

●Food-grade rubber sealing materials, mechanical seals can be equipped with built-in, exterior-mounted, double-machine-sealed structures according to actual needs, and the sealing springs are not in contact with liquids;

●The self-locking impeller nut is used to avoid the accident of the impeller falling off due to frequent starting;

●The overcurrent part is made of SUS316L, which is suitable for most liquid transportation needs.

●The 1.5kW and 2.2kW power pumps are made of Nikoni's self-made stainless steel casing motor. Other power pump standards use IEC high-efficiency three-stage motors (also available according to user requirements). Efficient three-stage or different explosion-proof motor and protected by a stainless steel plate cover for overall flushing.

●The motor is mounted on an adjustable anchor bolt bracket.

Product Performance

●Flow range: 3 ~ 120 cubic meters / hour

● Pressure range: Maximum inlet pressure 0.5Mpa

Maximum exit pressure 1.5Mpa

●Motor Power: 1.5 ~ 22kW

●Applicable temperature: -10 ~ 120 °C

●Inside polishing: surface roughness Ra0.4 (medical grade)

Surface roughness Ra0.8 (food grade use)

●Outside Polishing: Electropolishing (matt)

Product Usage:

●Food industry:

Dairy, juice, alcoholic products, oils, ingredients, syrup, purified water

●Pharmaceutical industry:

Raw material liquid, emulsion, purification liquid, essential oil

●Cosmetics:

●Chemical Industry:

Chemical solvents, cleaning agents, dyes, acidic or alkaline liquids, alcohols

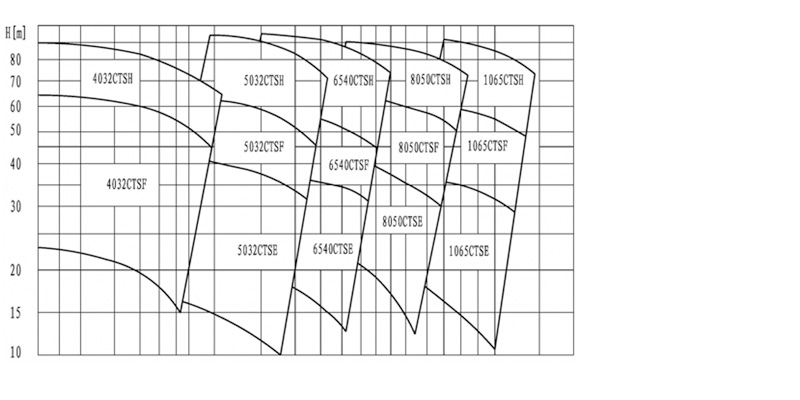

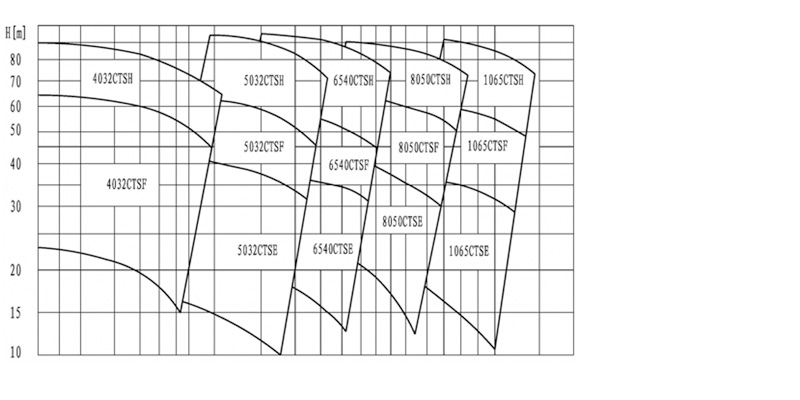

Performance curve: