CT series

Features and uses:

Product Overview

The CT Series Standard Chemical Process Pump is a standard chemical process pump designed to ISO2858. The pump is a single stage, horizontal, radial split volute pump. The pump body is supported by the pump foot, axially sucked, and discharged radially. The axial force balance is performed by using the front and rear mouth rings and the balance hole according to the conditions of use. The pump cover has a cooling or heating pipe joint. The shaft seal is sealed with a packing, or it can be single-end, series or double-faced mechanical seals, and equipped with a mechanical seal cooling and flushing system. The pump has the characteristics of good reliability and easy maintenance, and is especially suitable for applications in the petrochemical industry.

Product design implements ISO2858, ISO5199, and GB5656 design standards.

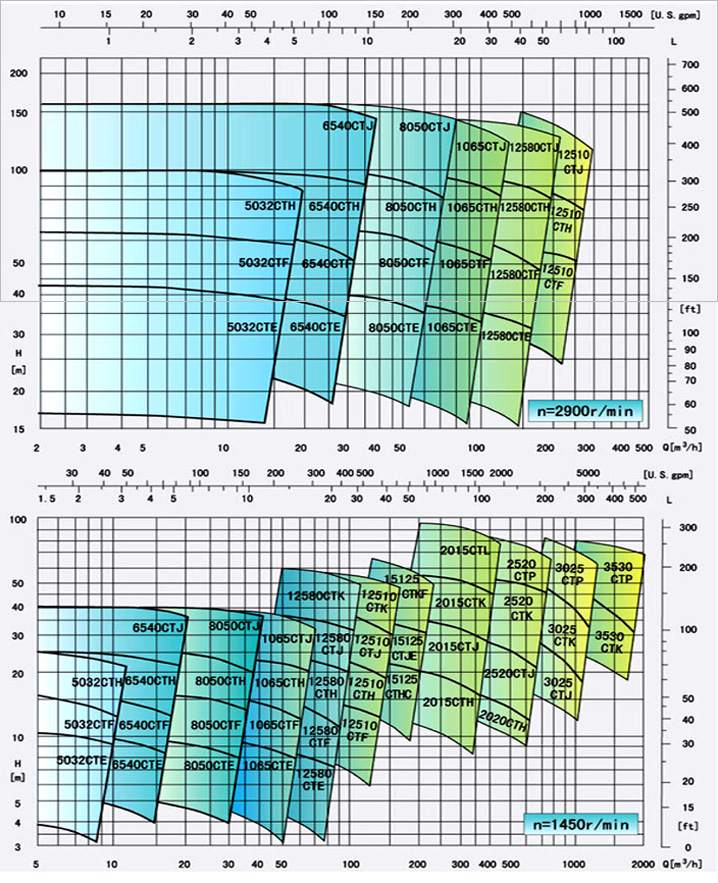

Performance range

Caliber (DN): 32-300m

Flow (Q): ~2000 cubic meters / hour

Head (H): ~160m

Working pressure (P): 2.5Mpa

Working temperature (T): -80 to +300°C

Speed: 2950r/min, 1475r/min

Product Usage

Mainly used in refineries, petrochemical industry, coal processing industry and cryogenic engineering, power, metallurgy, medicine, food, paper, pulping, desalination, ships And marine engineering to transport clean or contain particles, low temperature or high temperature, medium or corrosive liquids.

Suitable for transporting inorganic and organic acids such as sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid at various temperatures and concentrations; Alkaline solutions such as sodium hydroxide and sodium carbonate at various temperatures and concentrations; various liquid petrochemicals, organic compounds, and other corrosive liquids.

Performance curve: