INDUSTRY APPLICATION

Nikoni vortex pump - solve the water supply problem of small capacity medium and high pressure steam boilers

Small capacity medium and high pressure steam boilers, petrochemical industry and fine chemical industry have more demand for small flow high lift chemical process pumps. However, due to the small number of pump products suitable for small flow and high lift conditions, especially the varieties suitable for use as chemical process pumps are rare, many domestic chemical equipment manufacturers and users often have to use centrifugal pumps. Reciprocating pumps (including metering pumps), gear pumps or high-speed pumps to meet their respective equipment needs. This kind of helpless approach has many inevitable problems for chemical equipment.

1. Problems with centrifugal pumps

The use of centrifugal pumps in small flow high lift applications, because it is originally designed for high flow applications, it is often necessary to divert some or even most of the liquid with different lines to meet the small flow demand This method not only has the problem that the pump is bulky, the motor power consumption is large, the pipeline is thick, the reflow structure is complicated, the control is troublesome, and the like is similar to the big horse-drawn car. At the same time, there are still large initial equipment investment, long-term operation and maintenance cost. High problem.

If multi-stage centrifugal pumps are used to achieve high lift, there will inevitably be problems with complex multi-stage pumps, large operational inertia, unsuitable for sudden start and stop, and frequent failures. .

2, problems with reciprocating pumps

Reciprocating pump, although it has the characteristics of easily achieving high lift, its reciprocating characteristics inevitably cause high pulsation, even with a voltage regulator (or accumulator) The pulsation is completely eliminated. At the same time, when conveying high temperature and impurity-containing liquids, the reciprocating pump (plunger pump) often has problems such as many failures and high maintenance costs. Therefore, reciprocating pumps are generally not suitable for use conditions with high requirements for stable liquid delivery.

3. Problems with gear pumps

Because of the contact friction between the gears, the gears tend to have performance degradation due to gear wear during use, and at the same time, it is not suitable for conveying high-temperature liquid due to the limitation of metal expansion coefficient. .

4. Problems with high speed pumps

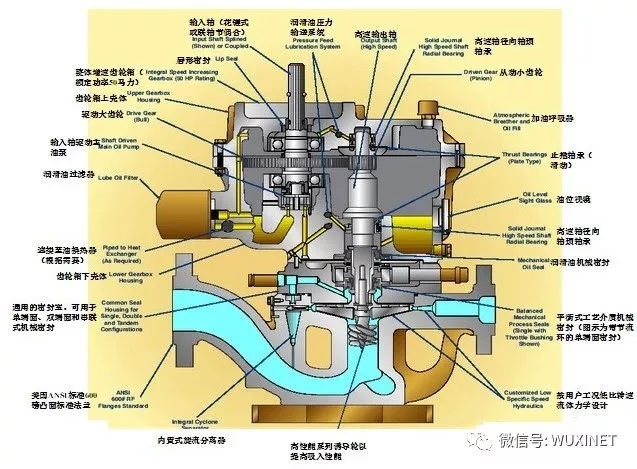

High-speed pump speed range between 3500-25000rpm, driven by the integral gear speed increase box. The integral gear speed increase box has a complicated structure. In order to control the vibration and noise level, the machining precision and overall fit precision of the component parts are very high, and a forced lubrication system is required to ensure its normal operation. High-speed pumps are not only costly to produce, but also expensive to sell, and the maintenance is complicated and the maintenance costs are correspondingly expensive.

One, vortex pump is suitable for small flow and high lift chemical process use

In the use of small flow and high lift, Nikoni vortex pump has the advantage that the above various pumps can not be replaced. Main features of the Nikoni vortex pump:

1. Small size and simple structure

Nikoni vortex pump has fewer flow components, small size, simple structure, and maintenance and repair is also very simple.

2, suitable for complex and demanding conditions

Many varieties of Nikoni vortex pump are designed according to special use conditions, with good cavitation resistance, high temperature resistance, suitable for gas-liquid mixing, etc. Small flow high lift or harsh service conditions that are difficult to handle with other pumps in chemical processes.

3. Reasonable design, high quality, long-term stability

Nikoni vortex pump has been continuously improved and optimized after more than 70 years, its unique design and excellent performance are at a high level. Strict material control and precision machining with CNC equipment provide reliable guarantee for product accuracy and quality.

The biggest difference between Nikoni vortex pump and domestic and even European and American similar products is the way the impeller is fixed. Nikoni ensures the concentricity and parallelism of the pump shaft and the pump impeller with precision machining, and fixes the impeller of the vortex pump to the shaft end. The gap between the impeller and the pump body is strictly controlled. In addition to the mechanical seal of the sliding parts, there is no direct contact and friction between the parts of the pump during operation, so the performance of the pump can be ensured for a long time.

4, the product line is rich and the scope is wide.

Nicconi has developed a wide range of products to meet the needs of industrial development to meet the high temperature, low temperature, low melting point, low flash point, easy boiling, flammable and explosive, highly toxic, with The need for radioactivity, ultra-pure and valuable fluids. Among the chemical process pump varieties, there are high self-priming varieties (~8 meters), ultra-low cavitation allowances (0.3 meters), heat medium varieties (~350 °C without cooling), gas-liquid or liquid-liquid mixed varieties, and The leak-free varieties of magnetic actuators have been widely used in the domestic petrochemical and fine chemical industries.

Nikonni vortex pump single-stage impeller can achieve ~17 kg pressure, double impeller can achieve ~30 kg pressure; pump diameter is 15 ~ 100 mm, easy for users in 0.1 ~ 50 cubic Select within the flow range.

According to the actual needs, Nikoni can also customize the products that meet API610 specifications for users.

Second, the application of Nikoni vortex pump in chemical process

1, in the production process of chemical products sulfoxide needs to transport the medium that is easy to gasification and contains impurities. The anti-gasification ability of the centrifugal pump is difficult to meet the production process requirements. Since the user replaced the original centrifugal pump with the Nikoni vortex pump, the problem that the user faced the frequent failures in the production process and the serious economic loss caused by the pump damage was completely solved. At present, Nikoni vortex pump has become one of the key equipment in the sulfoxide production process.

2, the conventional ammonia methanol production process requires a complex mixed reaction process and requires a variety of large equipment (pumps, valves, reactors, etc.) to achieve the production process. The conventional production process has the problems of high cost of production equipment, difficulty in operation and maintenance, environmental pollution caused by gas leakage, and long-term high production cost.

Users using Nikoni vortex pump to replace the original mixed reaction process and related equipment, not only easily achieve the goal of simplifying the process, but also reduce equipment investment and reduce production costs, but also from Fundamentally solved the problem of environmental pollution.