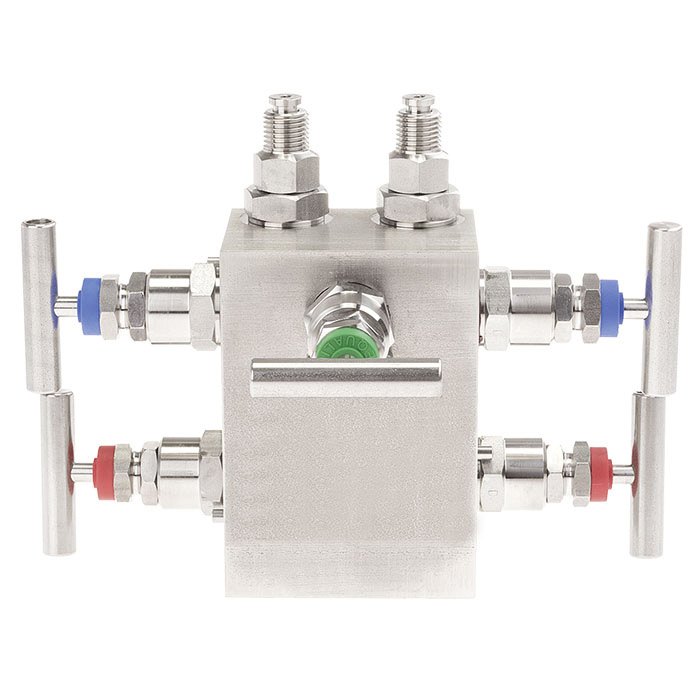

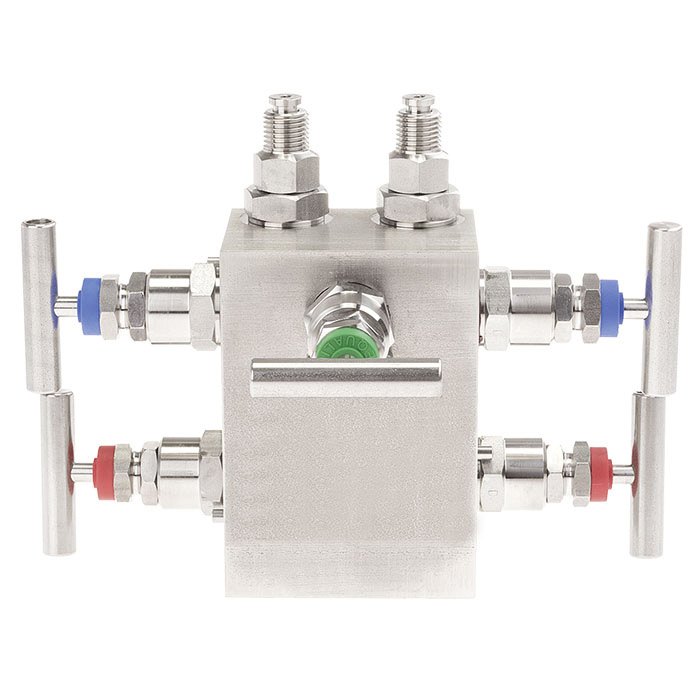

IV30, IV31, IV50, IV51 valve block

|

|

Application of the valve group

Blocking, pressure compensation, cleaning and pressure relief of differential pressure measuring instruments

Applicable to non-highly viscous or crystalline gas and liquid aggressive media, also suitable for corrosive environments

Process Industry: Oil and Gas, Petrochemical, Chemical, Power Generation, Water and Wastewater Treatment

Functional characteristics of the valve group

Low wear design, the spindle head in the bonnet is not rotatable

The valve handle has low torque and can run smoothly even under high pressure

Explosion-proof bonnet design enhances product safety

Can be combined with valves and instruments (connections) according to customer requirements

Standard center distance is 37 mm and 54 mm for WIKA differential pressure gauges and general process transmitters

Description of the valve group

IV30 and IV31 three-valve group

Three valve group consists of two blocking valves and a pressure compensation valve. The blocking valve separates the process from a measuring instrument such as a pressure gauge, switch or transmitter. The pressure compensating valve ensures that the pressure is compensated between the ⊕ face and the face to avoid unilateral overpressure during commissioning and operation.

IV50 and IV51 five-valve group

Compared to the three-valve, the five-valve is equipped with two additional discharge valves. The one-sided pressure bleed valve ensures operator unilateral pressure discharge and, in addition, bilateral pressure relief.

The valve head spindle head is not rotatable to reduce the wear of the sealing element. This also significantly extends the life of the product, especially when it is frequently turned on and off.

Valves are explosion-proof to improve their work safety, especially under high pressure loads.

WIKA fits the valve and pressure gauge perfectly together and incorporates this service with other accessories into a direct-install solution, also known as a connection. To ensure the performance of the entire system, leak testing is also performed when making connections.