Importance of boiler deoxygenation

In the boiler feed water treatment process, oxygen removal is a very critical part. At present, China's boilers use demineralized water or desalinated water as boiler feed water. Because oxygen corrosion is a slow process, some enterprises do not pay attention to boiler feed water deoxidation. On the other hand, due to the lack of stable and reliable deaeration technology, the problem of dissolved oxygen corrosion in boilers in China is quite prominent, especially in the field of industrial boilers, which causes the average life of industrial boilers to be shortened by more than 1/3, causing huge economic losses to enterprises and countries. .

Boiler oxygen corrosion generated substances mainly iron oxide will deposit or adhere to the boiler tube wall and heating surface, forming insoluble iron and poor heat transfer, iron scale will cause pits on the inner wall of the pipe The thermal resistance coefficient increases. When the pipeline is seriously corroded, it will cause pits on the inner wall of the pipeline, and the thermal resistance coefficient will increase. When the pipeline is seriously corroded, a pipeline explosion accident will occur.

The traditional oxygen removal methods mainly include: thermal oxygen removal, analytical oxygen removal, sponge iron oxygen removal, vacuum oxygen removal, chemical oxygen removal, etc. These deoxygenation technologies have certain limitations, The energy consumption is high, and some detoxification brings impurities harmful to the boiler, causing secondary corrosion and pollution to the boiler, and some deoxidizing effects are unstable, making the traditional oxygen removal method difficult to use in industrial boilers alone. Achieve the expected oxygen removal index.

For many years, boiler feedwater treatment workers have been exploring efficient, economical and environmentally friendly oxygen removal methods. The Nordic Vera Membrane Deaerator (E-MDO) came into being and obtained national patents. .

The principle of deoxidation of membrane deaerator

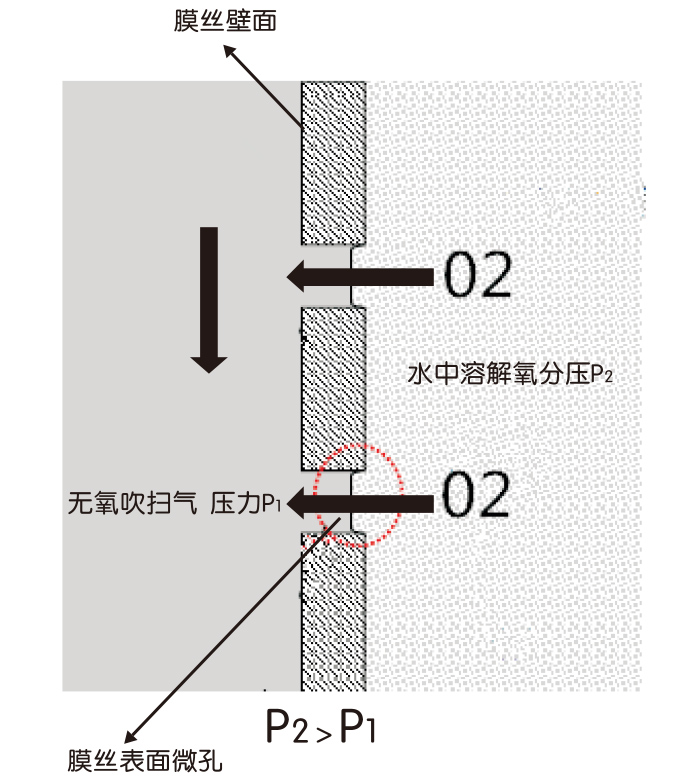

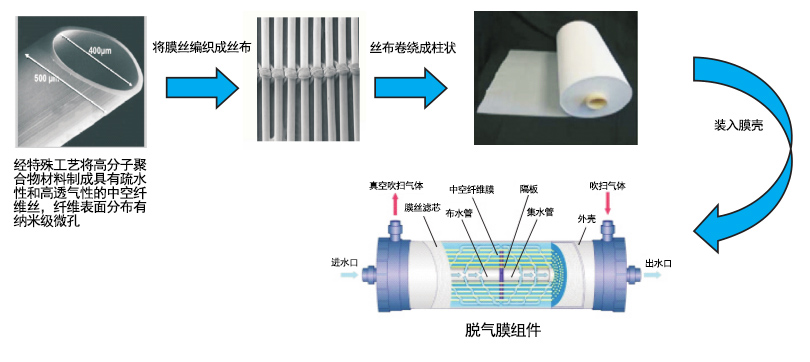

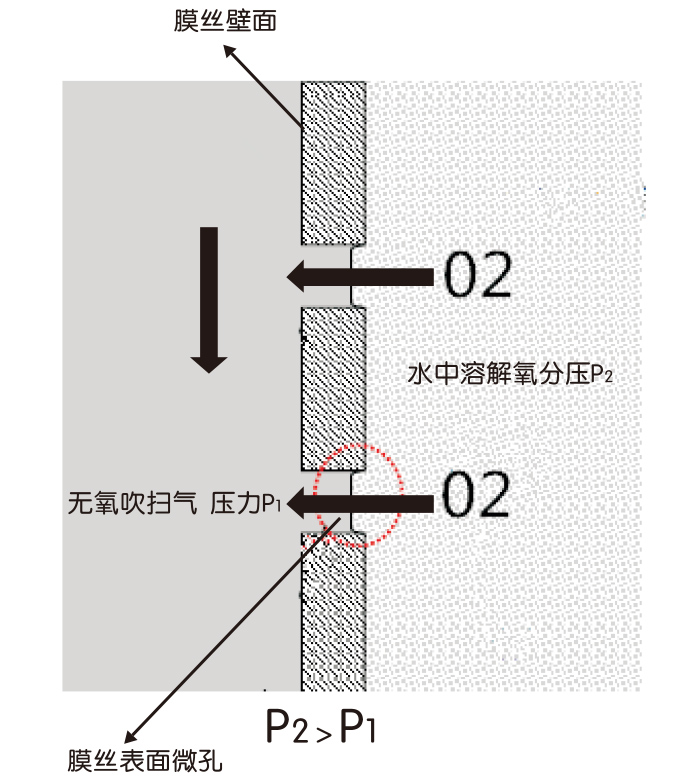

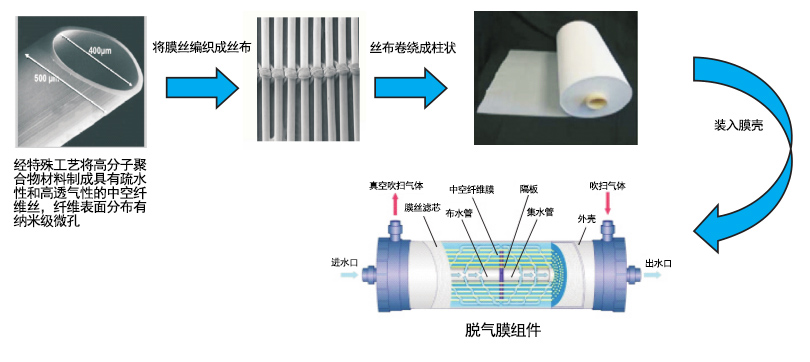

Nordic Vera Membrane Deaerator is a purely physical method for gas-liquid separation technology, using hollow fiber membrane filaments made of high molecular polymer materials, the surface of the membrane has numerous nano-scale micro Holes, these pores have a gas permeable and opaque function, thereby establishing a gas-liquid separation interface, and then according to Henry's law and Dalton's law of partial pressure, by changing the total pressure of the gas phase, the dissolved oxygen dissolved in the water is precipitated and discharged to reach the water. Deoxidation purpose.

|

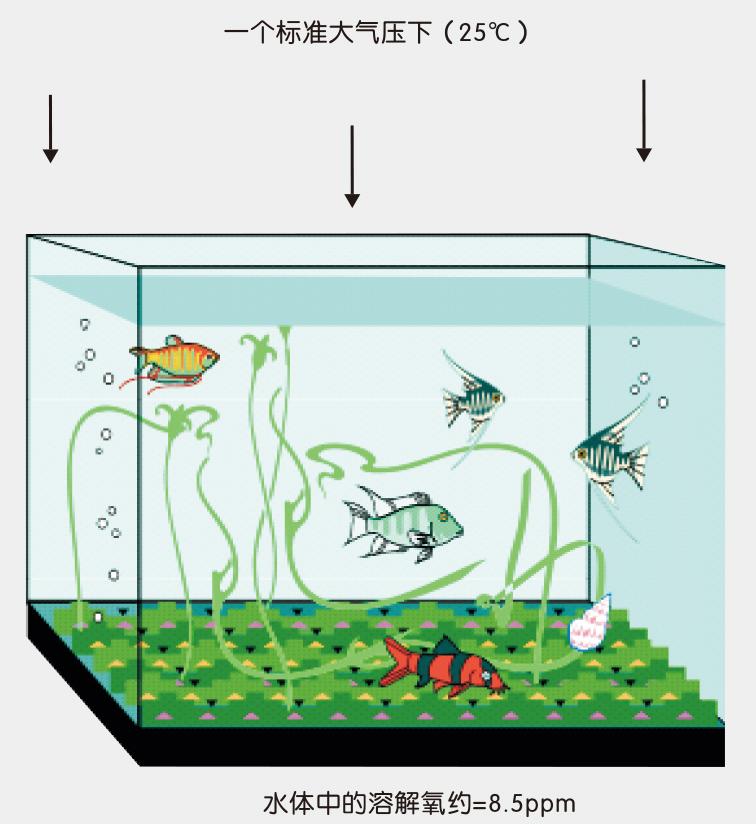

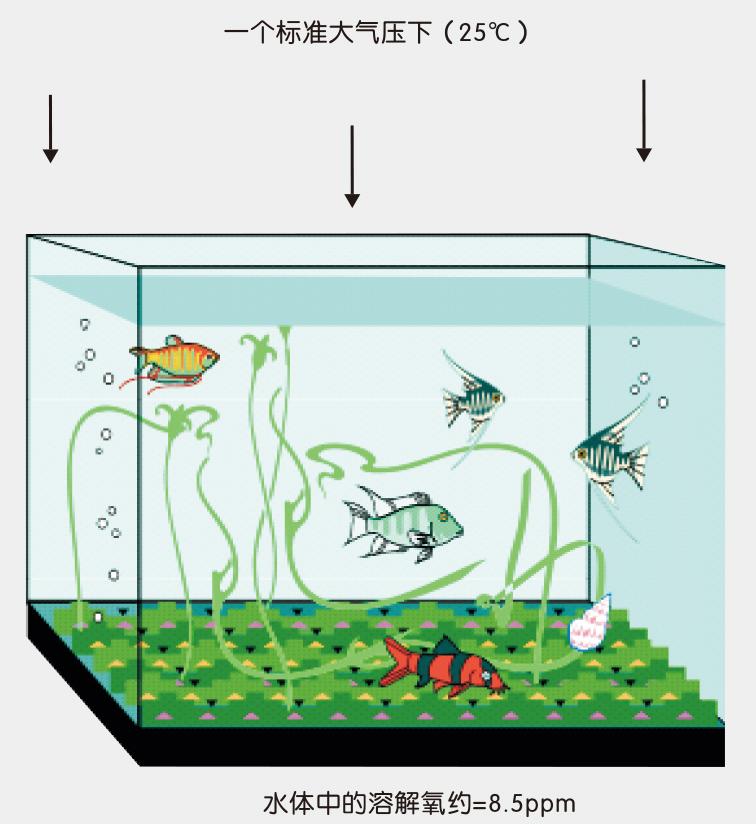

Henry's Law

When the gas is in contact with water, the gas will dissolve in the water;

The solubility of the gas in water is proportional to the partial pressure of the gas on the surface of the water;

Henry's Law: P=Hx

P=the partial pressure of the gas on the water surface

H = Henry coefficient of the gas

X = solubility of the gas

|

|

Dalton's law of partial pressure

The partial pressure produced by a gas in a gas mixture is equal to the pressure produced when it occupies the entire container at the same temperature; the total pressure of the mixed gas is equal to the sum of the partial pressures of the gases. |

|

Technical introduction

Membrane deaerator works the same as the vacuum tower, but the tens of thousands of hollow fiber membranes (such as hair thin) of the membrane deaerator provide a hundred times higher gas-liquid exchange than the vacuum tower. According to the formula Q=K*A*ΔP, when the degree of vacuum ΔP is the same, the larger the exchange area A, the larger the amount of removed gas Q, where K is the correction factor.

The core component of the membrane deaerator is the degassing membrane module, which is produced as follows:

Advantages of Membrane Deaerator

Operating at room temperature, no need to consume steam, greatly saving energy;

pure physical methods, do not increase salt in water, no secondary pollution problems;

The equipment is small in size, light in weight, and can be placed at any position, greatly saving capital investment;

Low operating costs, in addition to consuming a small amount of electrical energy, no longer consume any other substances;

can remove oxygen and carbon dioxide from water;

Fully automatic control, suitable for long-term operation, insensitive to drastic changes in load, always up to standard;

Long service life, degassing membrane module for at least 5 years of service life;

Low placement, no pump cavitation problems, greatly extending pump life and reducing pump power consumption;

Simple expansion of capacity through parallel degassing membrane modules;

The series of degassing membrane modules can easily achieve dissolved oxygen removal in water;

Create favorable conditions for the full utilization of low-temperature waste heat of clean fuel boilers, making it possible to vent condensation;

Applicable to all kinds of high, medium and low pressure boilers;

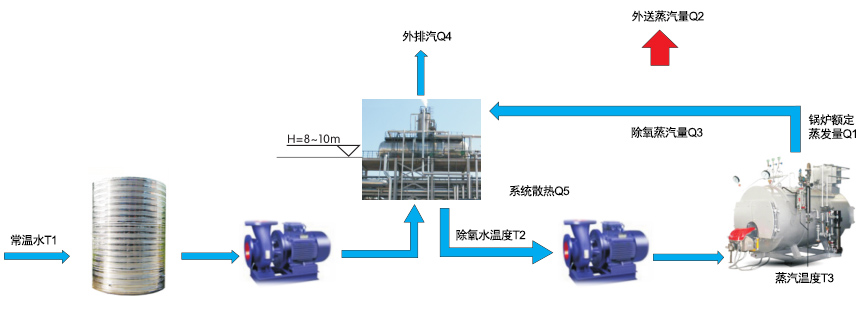

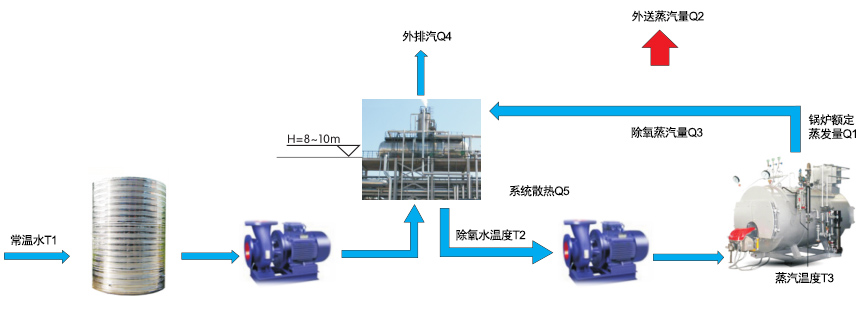

Process of heat deaerator boiler water supply system

Process of membrane deaerator water supply system

Boiler Oxygen Removal System Advantages over Thermal Deaerator System

1, membrane deaerator equipment is highly integrated, the installation site only needs to be connected to water and electricity, greatly reducing the installation cycle and investment;

2, the system does not need an oxygen pump, reduce the corresponding pumps, valves and control components, reduce investment;

3, membrane deaerator with low position, can greatly reduce the construction height of the boiler room, saving investment and construction cycle;

4, membrane deaerator does not need steam heating and exhaust steam, and the system operates at room temperature, no heat loss, energy saving is obvious.

The membrane deaerator system is more energy efficient than the thermal deaerator system

1, thermal deaerator energy loss mainly includes two parts: exhaust steam loss Q4 and system heat loss Q4. After calculation, Q4+Q4≈ 1.3% Q1 (boiler rated evaporation), actual delivered steam quantity Q2=98.7%Q1.

2, the operating costs of thermal deaerator mainly include: power loss, power consumption, equipment depreciation, etc., such as boiler fuel for natural gas, unit price is 3.0 yuan / m3; electricity price is 0.7 yuan / kWh Calculate, the deoxidation cost of the thermal deaerator ton water is 3.8 yuan.

3, membrane deaerator operating costs are: power consumption and equipment depreciation. The electricity price is calculated at 0.7 yuan/kWh, and the oxygen deoxidation cost of the membrane deaerator is about 0.25 yuan.

4, comparative analysis of membrane deaerator and thermal deaerator:

(1) oxygen depletion cost ratio: membrane deoxygenation water deoxidation cost & asymp; 6.6% thermal deaerator water deoxygenation cost;

(2) Take the 10t / h deaerator as an example, replace the thermal deaerator with a membrane deaerator, and recover the cost in 8 months.

Comparison of Membrane Deaerator with Conventional Deaerator

Selection of Membrane Deaerator Specifications

1, membrane deaerator model specifications

Note: 1. According to the requirements of the user, our company can provide other types of membrane deaerator.

2. The data in this table is for reference only and is not used as the basis for product acceptance.

|

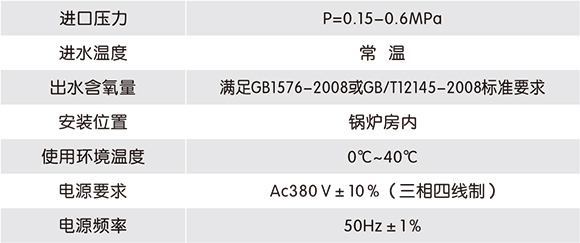

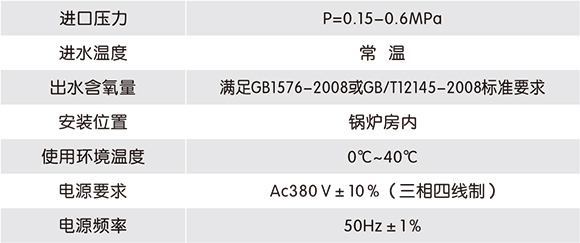

2. Membrane deaerator design parameters |

3. Requirements for raw water quality by membrane deaerator |

|

|

Note: The water content can be up to 1ppb, and the deoxidation requirement should be specified when ordering.